MCY Metal

MCY Metal San. ve Tic. A. Ş., which is active in the automotive and radiator sector in the field of sheet metal parts manufacturing. It has a total area of 5.000 m², 3 shifts, 110 employees and industry experience.

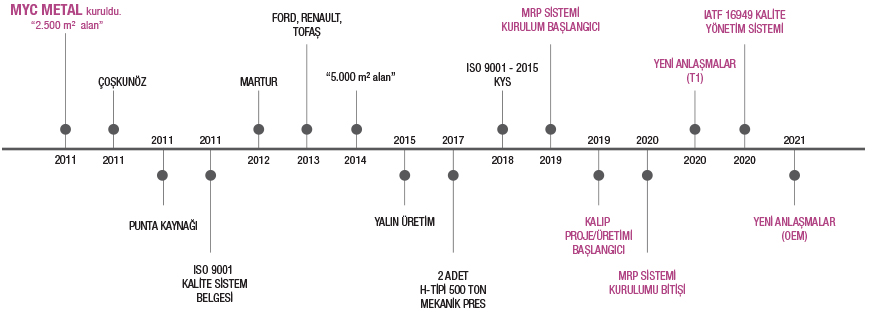

With the importance given to customer satisfaction; products, human resources, processes and environmental quality by continuously improving the supplier maintains its position. Since 2011 MCY Metal San. ve Tic. A. Ş. has TS EN ISO 9001 quality management system and aims to obtain MRP system in 2019 and TS 16949 quality system certificates in 2020.

Our goal is to become a preferred company as the main side industry, strategic business partner of our customers who produce automotive main supply industry and radiator in our country and abroad.

History

2011 – Mass production started with Coşkunöz Metal Form, Coşkunöz Radiator and Beltan Vibracoustik works.

2012 – Spot Welding was established and started production.

2012 – Mold maintenance department was established and we started to maintain our molds and fixtures.

2012 – We started to use ISO 9001 quality management system.

2012 – We started production of automotive seat parts with Martur.

2013 – Production of pressed and welded mass production parts for FORD / RENAULT / TOFAŞ automotive production lines under the leadership of Coşkunöz Metal Form was started.

2014 – We started to operate in 5000 m² area as production and transportation area.

2015 – In the year the assembly production department was modernized and the new spot welding machines and lean manufacturing system were switched to.

2017 – We have added 2 H-Type 500 ton presses to our capacity.

2018 - We passed ISO 9001 2015 Quality Management System.

2020 – The infrastructure was strengthened by providing new equipment such as advanced technology machines, drivers, devices and equipment to our Press Shop and Assembly production lines.

2021 – Our company started transitioning to the digital software module (EPOS) program within the scope of more effective management of business processes under advanced conditions.

2021 – Within the framework of our mission of continuous improvement and development, the IATF 16949:2016 certificate was obtained by transitioning to the Quality management standard covering the international automotive industry technical requirements.

2022 - We became a Joint Stock Company by changing its type on 26.12.2022.

2023 - In 2023, we added 1 H-Type 630 ton press to our capacity.